- Home

- Product

- Granule packing machine

- Factory price grain packaging machine for 500g rice

CONTACT US

SEND INQUIRY NOW电话: +86-757-81859859

电话: +86-18902413057

邮箱:soonkpack8618902413611@gmail.com

全自动一体包装机包装500克大米产品,该包装机采用SK-L420主机配合送料机及称重计量设备,配合成品输送机,对500克大米包装产品进行包装。

机械部件

1)主包装机,2)10头螺旋称重机,3)成品袋输送机

大米包装机的一些详细图片

智能工业级触摸屏

制袋机

纵封装置

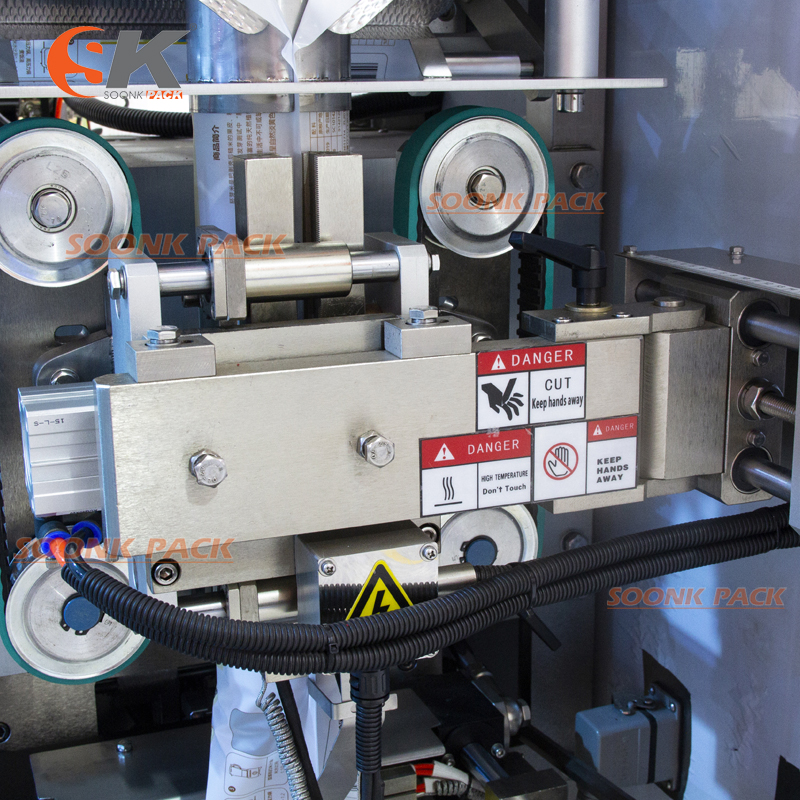

横封装置

10头秤

不锈钢收集料斗

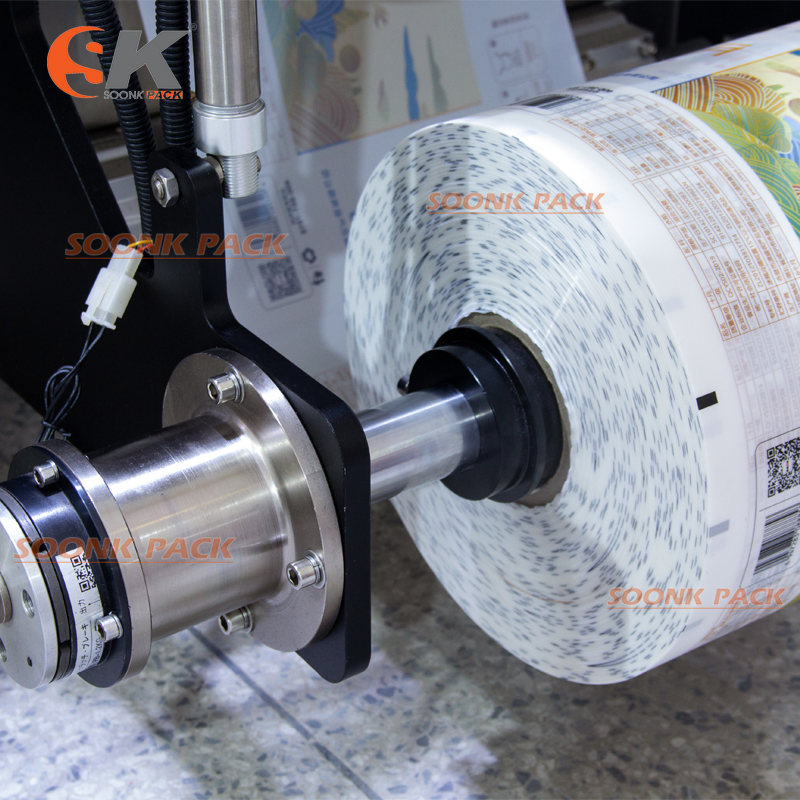

薄膜释放装置

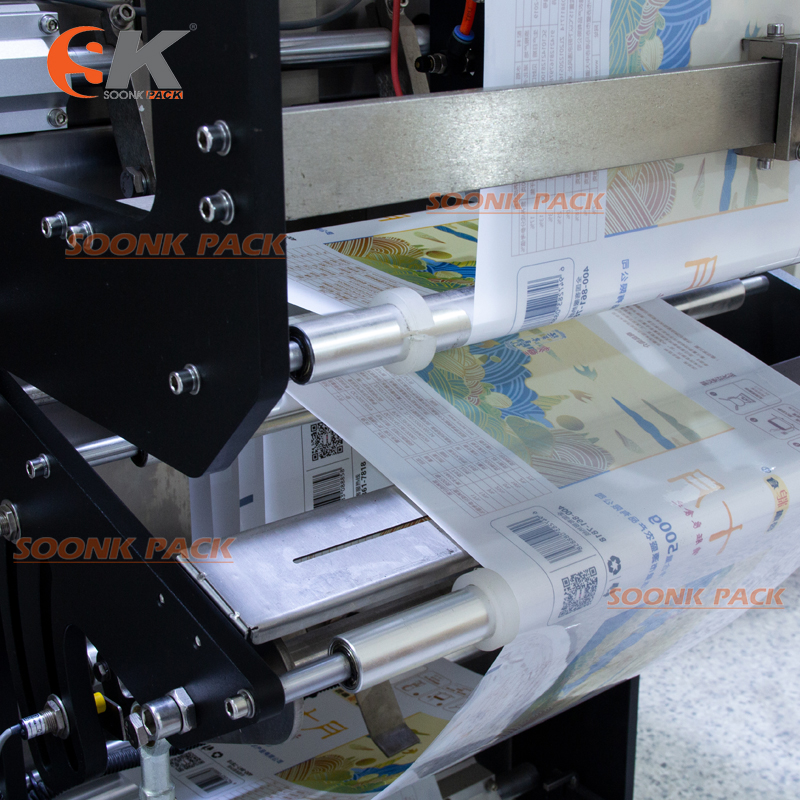

输膜装置

智能工业级触摸屏:灵敏度高,运行稳定,简单易懂,操作方便;三个温控表,独立控制,稳定可靠,制作出精美的包装袋

制袋机装置:制袋机是专门为包装冰块而设计的,与普通制袋机不同,主要针对冰块包装过程中遇到的潮湿、打滑等问题而设计,使薄膜能够顺畅运行并密封。

纵封装置:纵封装置结构紧凑,利用贴合原理,使薄膜瞬间热封,主要针对PE薄膜材质的特殊封口设计,使封口线封合整齐。

横封装置:横封装置设计独特,同样是专门针对PE膜物料封口而设计的。同时,横封部分配备了先进的夹袋装置,可以防止物料下料过程中因速度过快、重量过大而导致包装袋破损。同时,它与支撑装置配合,可以托住较重的包装袋,防止包装袋破损。

10头秤装置:采用步进电机,运转安静,运行稳定,寿命长。

不锈钢集料斗:针对流动性较好的包装物料,采用集料斗,有效防止物料到处散落。

输膜装置:输膜装置采用优质材料,表面处理光滑,无划伤,不损伤卷材,膜辊搬运转动灵活,间隙合适,包装卷材不跑偏,从而得到完美的制袋效果。

放膜装置:采用带刹车功能的放膜电机,使包装膜停止自如,不浪费卷材。放膜位置采用两圈加厚钢圈固定包装膜,不用担心卷材跑偏。

产品描述:

立式颗粒包装机广泛应用于各种颗粒状物体的包装,它的精度比较高,而且减少了物料的浪费,大大提高了动态颗粒包装机的产量。颗粒包装机的工作原理是,工作时,被包装好的物料从供料仓落入振动给料器,随着振动给料器振动,均匀地流入称量斗,当重量等于称量值时,停止给料,称量完成。

性能特点:

1、全自动五谷杂粮颗粒包装机主机采用不锈钢材质,整体结构设计紧凑、坚固、简洁;

2、采用直线四头组合秤称重计量,微机控制系统,采用双振动给料,数字传感器,计量瞬时准确。

3、四头称量斗可快速拆卸,方便清洗维护。

4、包装机一次性自动完成物料称重计量、制袋、产品下料、生产日期打印贴标、产品充填、封口、切断、输出。

5、采用伺服双拉膜系统,保证纸膜输送顺畅,制袋平整;

6、采用进口品牌气缸,确保袋子封口性能良好,封口线清晰;

7、采用进口PLC电脑控制系统,运行更稳定,不停机可调整任何参数。

8.采用伺服电机拉膜,定位更准确。

9、包装形式多样化,如背封、角撑板、连袋、冲孔等。

大米包装机注意事项:

第一:每次开机的时候都要检查一下包装机周围的环境,看看是否有影响包装机的现象。

第二:大米包装机开始工作后,应尽量远离机器,特别是不要将头部、手指或身体的其他部位接触到包装机的运转部分。

第三:包装机在工作过程中,不允许任何物体伸入机器的封刀内,否则会损坏机器。

第四:在包装机工作过程中,切记不要连续地切换操作,也不要改变其参数设置。

第五:不能让大米包装机长时间处于高速运转状态。

第六:两个按钮不能同时切换,各种开关、按钮也不能同时操作。我们在维护保养包装机的时候,应该切断电源。在维修调试的时候,对大米包装机进行改造之前,应该仔细考虑清楚。

1)每次开机前,需检查机器周围是否有异常;

2立式颗粒包装机运转时,禁止用身体、手、头、头发接触工作部件;

3)立式颗粒包装机运转时,禁止用手或工具阻挡封刀座,不要触摸横、纵封滚轮,否则会被烫伤;

4)机器正常运行过程中,禁止频繁切换操作按钮,禁止随意更改参数设定值;

5)包装过程中不得混入异物,否则可能造成出料堵塞、不准确或机件损坏;

6)立式颗粒包装机储料活塞、出料缸下端密封圈应及时更换。

立式颗粒包装机工作结束后,我们需要清理机器,为第二天的工作做好准备。定期给立式颗粒包装机的齿轮啮合处、轴承座油孔和运动部件加注润滑油。加润滑油是为了润滑。加润滑油时,切勿将润滑油滴在传动平带上,以防止打滑或加速皮带老化。

各类不规则、颗粒状、块状、条状、精度要求高、易破碎的散装包装,如膨化食品、虾、薯片、水果片、砂锅、花生、瓜子、糖果、饼干、蚕豆等。

|

产品名称 |

SK-L420D10T小袋大米包装机 |

|

空气消耗量 |

0.65mpa,2.5m³/min,6kg/cm² |

|

包装膜宽度 |

420毫米 |

|

袋子长度 |

80-300毫米 |

|

袋子宽度 |

80-250毫米 |

|

线圈最大外径 |

最大360毫米 |

|

包装速度 |

15-60袋/分钟 |

|

包装膜厚度 |

0.04-0.08毫米 |

|

电源规格 |

220V.50/60Hz.2.8KW |

|

方面 |

(长)1450*(宽)1000*(高)1650mm |

|

包装材料 |

复合膜 |

立式食品包装机械设备安全使用注意事项及维护方法

立式食品包装机械设备主要用于包装食品。无论过去还是未来,食品卫生安全始终是人们最关注的问题。因此,立式食品包装机械设备的材质和设计都符合食品卫生安全的要求。

很多食品厂在购买立式食品包装机械设备时,对于立式食品包装机械设备的安全注意事项以及维护保养方法并不清楚。

立式食品包装机械设备安全使用注意事项:

1、购回的包装机应放置在干燥、无阳光直射的地方;

2、在安装立式食品包装机械设备之前,先检查其电压和功率,避免接电时出错,造成不必要的损坏。不同的立式食品包装机,电压和功率是不同的;

3、为了安全,包装机应配备带有接地线的电源插座;

4、开机前检查设备有无故障,对食品接触器具进行消毒,确保食品卫生;

5、若设备发生故障,应关闭所有电源开关,并注意不要触摸横、纵封的位置,以免烫伤。

立式颗粒包装机组合秤校准后仍然不正常是什么原因

社会的不断发展使得自动化的发展速度越来越快,很多产品都可以通过自动化来替代人工,降低人工成本。

对于我们行业来说,自动化设备替代人工包装,实现全自动化包装。不同状态的产品需要采用不同的自动化设备进行包装,比如颗粒状的物料,我们建议采用立式颗粒包装机进行包装。

立式颗粒包装机可以根据自身企业的需求选择不同的称重计量装置。不同的称重计量装置所满足的要求也不同。对于精度要求高的企业,我们建议使用组合秤进行称重计量,但是组合秤的价格相对较贵。

我们在调试立式颗粒包装机的时候,需要测试组合秤各个秤的精度是否一致,但是测试之后发现组合秤的秤经过校准之后仍然显示异常,那么是什么原因导致的问题呢?

立式颗粒包装机组合秤料斗校准时,仍出现异常的原因有:

1)检查秤斗、秤挂件是否控制其他物品;

2)检查使用校准码的重量是否正确;

3)检查校准过程是否正确;

4)检查传感器是否损坏。

如果立式颗粒包装机组合秤的料斗在校准后仍然出现异常,我们会按照以上四个步骤逐一检查,从而有效节省无法开机的时间。立式颗粒包装机组合秤适用于包装各种颗粒状产品。

Related Products

CONTACT US

Foshan Soonk Packaging Machine Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us